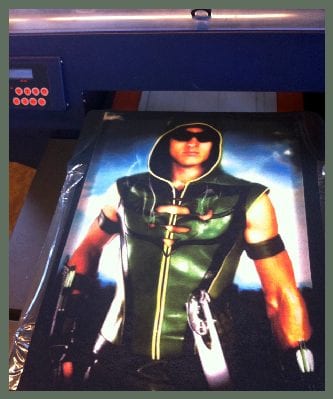

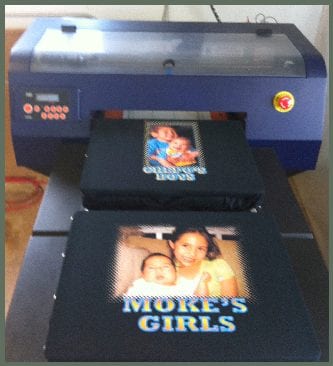

DTG Digital Direct to Garment T-Shirt Printing

Full color digital direct imaging on apparel. Order just one, no minimums. Large format

DIGITAL TEE SHIRT PRINTING

Digital

Why choose Direct to Garment computer imaged tee shirts over silk screened?

Here are just a few of the advantages…..

- Get just one, full color item!

- Get a few full color affordably.

- Water based inks ( environmentally friendly with a soft feel)

- No set up charges. ( silk screen stencil )

- No ink mixing. No press registration.

- No mechanical art or films.

- Hi resolution (4800 pixels per inch).

- Large format print ( 16″ X36″ )

- Millions of colors at no extra charge.

- Quicker turnaround time.

We’ve made it even easier and more cost effective with our new online designlab. This software allows you to upload your photo or graphic, add clip art, text and much more all for FREE, saving you from an art charge to produce a high resolution professional file. Our Viper print system uses a white ink management system that allows us to print on any color t-shirt including black and dark colors.

The disadvantages:

This process does not allow for quantity discounts.

It can’t print custom colors

Pantone color matching not possible.

Direct to

Most DTG custom shirts and garments can be produced in just a few days. This only depends on the demand. Holidays are typically a busy time as custom printed t-shirts are a great way to celebrate any occasion.

Unlike the heat transfer t-shirt imaging of the

Want something more amazing then just clip art and typography? Our professional

Digital t-shirt printing is starting to come of age. Since BASF has developed a white ink for use in bubble jet and

What are the pros & cons of digital tee shirt imaging as compared to other processes like heat transfers, sublimation or silk screen printing?

Unlike heat transfers or sublimation, digital printing can now be done right onto colored garments as a white ink can be applied first. Heat transfers do come in white,

HERE IS A BREAKDOWN OF SOME OF THE PRO’S & CON’S OF PRINT ON DEMAND CUSTOM T-SHIRTS AS COMPARED TO THE INDUSTRY STANDARD OF SILK SCREENING.

PROS….

1.) PRICE: There are no set ups associated with this form of reproduction. This means mechanical color separated films and screens are not needed. This is a major cost saving factor and has made it affordable to do just one or two full color printed items. Please see the number one con as an opposite effect of this.

2.) TIME: If you find a shop that does not have a lot of orders going on at the time, it is possible for shirts to be done while you wait do to the lack of set ups required.

CONS….

1.) PRICE + TIME: Digital printing is a slow process as compared to silk screening. With the silk screen process, once the job is set up , hundreds of full color garments can be produced on just one press in 30 minutes or less.

Digital printing may take that long just to spray one shirt. Silk screening can reproduce t-shirt quantities at 500 percent faster than digital.

This means you can get MAJOR price breaks for ordering quantities of silk screen printed shirts whereas digital printing does not give you a price break for quantities! This can be the difference from $3.00 bucks a tee compared to $8.00 to $20.00 a shirt.

Also in this area, is the fact that you pay the same price for a one color digital print as a full color digital print. Screen printing charges per color and can generate free mixed tertiary colors on press as well.

2.) QUALITY: Digital printing sprays the ink onto the garment whereas screening uses a squeegee with pressure to push the ink into the fiber, thus completely permeating the material. In fact most digital printers spray an alcohol down first just to get the ink to slightly absorb into the textile weave a few millimeters below the surface. Screen printing can also use different meshes of screen to adjust thick or thinner deposits of ink.

These inks fade quickly from sunlight, laundering and wear. Silk screened shirts…. “I still have a Pink Floyd shirt from the seventies, the shirt is falling apart but the print still looks great”.

3.) SPECIAL EFFECTS: Unlike silk screening, digital print on demand cannot print creative custom effect inks like.. glitters, shimmers, metallics, glow in the dark, neon, fluorescent black light, puff & raised, color changing ultra violet chromatic, clear gel gloss, foils, suede, light reflective, vinyl, Lycra & specialty material inks, as well as exact pantone color match inks.

Color matching, digital cannot do a color match! In fact, re-orders may result in an image that is completely different in color!

3-D effect, digital printing does not offer killer effect that can be done by a screen printer like, high density printing, fake process, indexing, flamingo printing and a whole host more.

Digital direct to garment is ideal for getting just one full color, large format printed clothing item. No art or set up charges, fast turn around. Item needs to be 100% cotton. Currently, we do not print supplied goods due to the spoilage rate associated with this process.

DIGITAL DIRECT TO GARMENT T-SHIRT PRINTING OR (DTG).

WHAT IS IT? WHY USE IT?

Unlike the heat transfer shops of the late 1970’s where you would go to a mall shop or store and look through catalogs of pre-made art and designs and select one to be heat pressed onto a t-shirt, digital direct to tee shirt printing actually takes any digital image or photo and prints it directly onto the garment. This technique uses a modified ink or bubble jet printer with custom water-based inks to print in stunning 4800 dpi detail and color.

Our dtg viper t-shirt printing system uses a modified Epson 4800 printer with a custom white ink management system. It’s print bed area will print a full color digital tee shirt with a stunning 16″ X 32″ image area.

Unlike traditional silk screen printing for custom made tee shirts, this allows us to print just one full color garment with no set ups or screen stencils, and no per color cost. Prior to this technique, printing just a limited amount of custom shirts in full color was to expensive. And most printers would not print just one shirt with just one color as this was to time consuming and expensive.

Digital direct to garment printing allows you to now create and order just one full color custom t-shirt or hooded sweatshirt at an amazing cost. The detail and color brightness is amazing. the effects go from photographic in nature to looking like hand airbrushed art or even pencil sketches and oil painting.

So, why would you choose traditional silk screen printing over direct to garment?

Silk screen printing is the standard for making custom tee shirts and printed apparel. It’s been around a long time and has been honed and perfected. With DTG shirt printing, there are several limitations. While the ink is now color fast and will hold up to repeated washing and laundering, the print process itself is limited to the CMYK color gamut. CMYK stands for the four inks used in computer printers. ( just like the one on your desk) Cyan ( Blue) Magenta ( Red) Yellow and K ( Black). Between these four colors, the printer can generate some 25,000 tints tones and color blends.

Unfortunately, many things created with computer graphics use the RGB color spectrum or gamut. R ( Red) B ( Blue) and G (Green) these are the three colors of the light emitting diodes of a digital display like tv’s smartphones, computer monitors and such. This color spectrum can create some very intense neon colors that cannot be reproduced with the CYMK gamut.

Another limitation of digital tee shirt printing is color accuracy. Many company logos and graphic designs use a specific color or hue. Digital imaging cannot reproduce an accurate color each time. In fact, many times what the customer thought was a blue image may print on the t-shirt looking purple. A flesh-tone may look like a suntan or sunburn.

Silk screen printing on the other hand offers complete color accuracy as well as a host of custom inks from EVERY spectrum. Some of the inks offered with the traditional screening process are…

- Neon & Day Glow fluorescent black light

- Metallics Glitters & Shimmers

- Color Changing photo-chromatic

- Puffs & Foils

Learn more about garment decoration. Get deals & info about new products

Blog subscribers get email updates monthly. Automagically.